What is a Lithium Iron Phosphate Battery?

A lithium iron phosphate battery refers to any lithium-ion battery with lithium iron phosphate as its cathode material. These batteries feature high operating voltage, energy density and cycle life as well as good safety performance; low self-discharge rate; no memory effect, good high-temperature performance as well as light weightness and environmental friendliness are some characteristics that distinguish lithium iron phosphate from other options on the market; lithium iron phosphate is typically chosen over alternatives when power lithium-ion batteries come into play.

Lithium iron phosphate batteries (LFP batteries) are lithium-ion batteries composed of an LFP cathode, graphite anode, electrolyte and separator.

Mechanism of lithium iron phosphate battery

Lithium iron phosphate batteries feature charge and discharge reactions between their two phases: LiFePO4 and FePO4. During charging, lithium ions slowly separate from LiFePO4 to form FePO4, while during discharging lithium ions bind back together within FePO4 to form LiFePO4.

As the battery charges, lithium ions move from its lithium iron phosphate crystal surface towards its surface under the influence of an electric field. From here they enter the electrolyte, pass through the separator, and migrate towards graphite crystal surface before becoming embedded within its lattice network.

At the same time, electrons flow from the conductor through an aluminum foil collector of the positive electrode to its aluminum foil collector in an aluminum foil collector of an aluminum foil positive electrode collector, where they pass through tabs for battery positive pole post, external circuit, negative pole post, negative pole tab, copper foil collector of battery negative electrode and then graphite negative electrode to balance its charge before going back through conductor to balance charge between these negative electrodes; after lithium ions have been deintercalated from lithium iron phosphate, which converts back into iron phosphate as lithium iron phosphate becomes iron phosphate.

As the battery discharges, lithium ions become deintercalated from graphite crystals and enter the electrolyte, where they travel through a separator before reaching its surface where they reenter their lattice of lithium iron phosphate crystals to recombine into them again.

At the same time, electrons move from the conductor through to the copper foil collector of the negative electrode, then flow along a circuit that includes tabs for battery negative pole posts, external circuits, positive pole posts and tabs before arriving at an aluminum foil collector for the positive electrode of a battery positive cell. After becoming embedded within iron phosphate crystals via lithium ions embedding themselves within these crystals; iron phosphate transforms into lithium iron phosphate.

Lithium iron phosphate batteries exhibit many characteristics:

- High energy density

According to reports, mass-produced square aluminum-shell lithium iron phosphate battery cells currently offer an energy density of around 160Wh/kg in 2018. Some top manufacturers can typically reach an energy density between 175-180Wh/kg while exceptional manufacturers may use lamination processes and make larger capacities with even higher energy density that exceed this level.

- excellent safety performance

their cathode material has an extremely stable electrochemical performance, leading to an efficient charging and discharging platform. As a result, during charge/discharge cycles the structure of the battery does not change significantly and it won’t burn or explode; even under special conditions like short circuit, overcharging, squeezing or acupuncture, they remain very safe.

- Long Cycle Life

Lithium iron phosphate batteries typically boast a 1C cycle life that exceeds 2000-3500 cycles; for energy storage applications it must reach 4000-5000 cycles to guarantee 8-10 year service lives, far surpassing even that of ternary batteries which typically has cycle lives of 1000 times or so; long-life lead acid batteries have an approximate cycle life of around 300 cycles.

Lithium iron phosphate production has been nearly perfected and can generally be divided into solid-phase and liquid-phase processes. Of these methods, high temperature solid phase reaction methods are most often utilized. Furthermore, some researchers combine microwave synthesis in solid phase with hydrothermal synthesis in liquid phase to form what they refer to as microwave hydrothermal methods.

Additionally, lithium iron phosphate can be produced through various synthesis methods that include bionic synthesis methods, cooling and drying methods, emulsion drying methods and pulsed laser deposition processes. With such techniques in use, products with smaller particle sizes and better dispersion performance can be produced, which in turn shorten the diffusion path for Li+, increase contact area between two phases and speed its diffusion speed.

Industrial Chain of Lithium Iron Phosphate Batteries

China’s lithium iron phosphate battery industry chain starts with cathode materials, anode materials, copper foil electrolyte solution and separator equipment; then battery cells, battery management systems and energy management systems which are eventually packaged up as lithium iron phosphate batteries; while downstream applications include new energy vehicles, energy storage batteries (NEVES), new energy power generation side energy storage (NEPS), 5G base station energy storage (5GBSES) replacement, lead acid replacement batteries as well as lead acid replacement – finally power battery recycling – ending up at the aftermarket level.

Application of Lithium Iron Phosphate Batteries

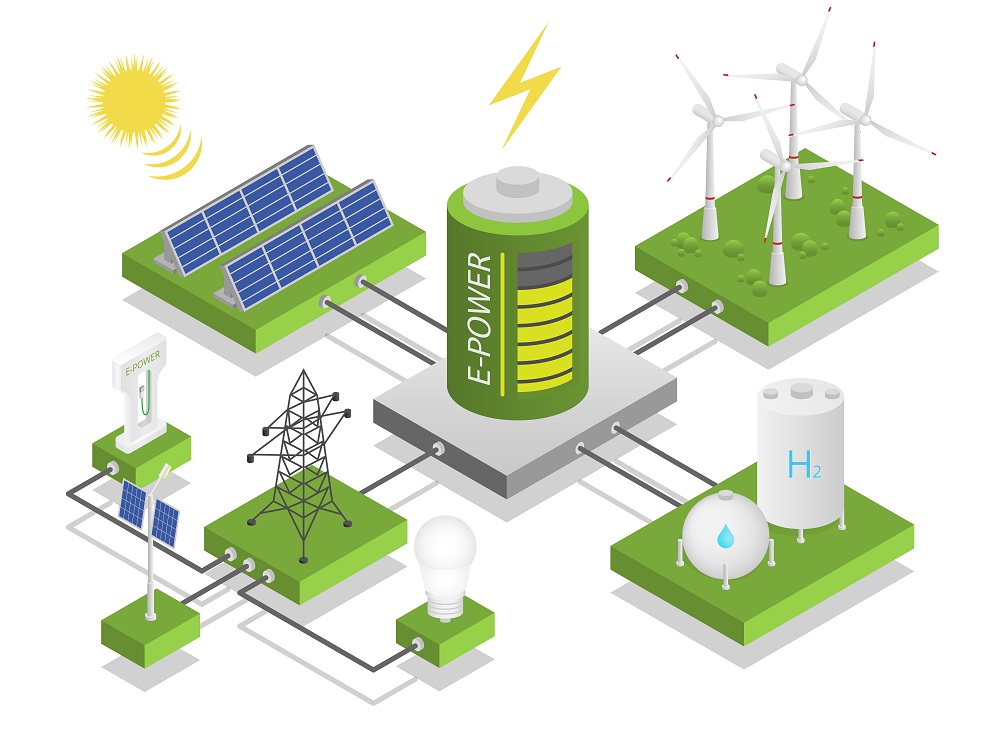

LiFePO4 batteries provide stepless expansion and large-scale energy storage solutions, making them suitable for applications including safe grid connection of renewable energy power stations, grid peak shaving, distributed power stations, UPS power supplies and emergency power supply systems.

Electric vehicle (EV) applications

LiFePO4 batteries have become widely utilized for electric vehicle (EV) applications such as passenger cars, buses, logistics vehicles and low speed electric vehicles due to their advantages of low safety costs and cost efficiency. Lithium iron phosphate batteries play a crucial role in these areas due to their durability; lithium iron phosphate accounts for half of total battery shipments annually according to recent data.

Startup Power

A startup lithium iron phosphate battery not only has the same characteristics of power lithium batteries but also boasts instantaneous power output capacity. Power lithium batteries with capacities less than one degree replace traditional lead-acid batteries; their instantaneous output capacity makes this solution suitable not only for starting-stop but also engine shutdown, coasting, braking energy recovery, acceleration power and electric cruise functions.

Energy Storage System (ESS)

As the energy storage market has experienced rapid expansion in recent years, some power battery enterprises have launched energy storage businesses by creating lithium iron phosphate battery applications for new markets and developing an entirely new business model. A system featuring lithium iron phosphate batteries has become one of the leading choices on the market.

Renewable energy power generation systems

Large-capacity energy storage products have become essential tools in reconciling the conflict between renewable energy power generation and grid connectivity. As storage capacity and scale expand, as integration technology improves and costs continue to drop for such systems.

After conducting extensive safety and reliability tests, lithium iron phosphate battery energy storage systems are expected to become widely utilized for grid connection and power quality improvements of renewable energy generation sources such as wind and photovoltaic energy production – making renewable energy an uninterrupted power supply with no fluctuations or fluctuations.

Grid Peak Shaving

Pumped storage power stations have long been the go-to option for grid peak shaving, yet due to their complex construction requirements (two reservoirs: upper and lower), they are limited by geographical restrictions and difficult to build in plain areas; in addition, their construction requires extensive land coverage and requires high maintenance costs.

Lithium iron phosphate battery energy storage systems offer an alternative to traditional pumped storage power stations when dealing with peak loads on the power grid, without being restricted by geographic conditions, free site selection, reduced investment costs and minimal land occupation requirements, plus low maintenance costs – thus playing an integral part in grid peak shaving processes.

Distributed power stations

Large power grids present several disadvantages, with one of them being their inability to meet all quality, efficiency, safety and reliability requirements for power supply. Therefore, important units and enterprises often rely on backup power sources or multiple power sources as guarantees and backup plans.

Lithium iron phosphate battery energy storage systems have the ability to reduce or even prevent power outages caused by grid failures and various accidents, playing an essential role in assuring safe and reliable power for hospitals, banks, command and control centers, data processing centers, chemical material industries and precision manufacturing industries.

UPS Power Supply For Data Centers

With the surge of demand for Internet of Things and cloud computing data centers are becoming an integral component of new generation information industries.

UPS uninterruptible power supply systems rely on backup battery packs as the last line of defense against power outages, as well as being at the core of maintenance efforts and servicing activities. As lithium battery energy storage system technology matures and costs become more efficient, lithium batteries may no longer only serve as UPS power supplies in future applications.

Conclusion

Lithium iron phosphate batteries are an outstanding technological achievement, boasting incredible performance characteristics such as high energy density, safety and lifecycle durability that have enabled their widespread adoption across various fields – from electric vehicles and renewable energy storage solutions to backup power sources and backup systems. As technology continues its advancement we can anticipate further advancements in lithium iron phosphate battery design and performance that open up opportunities for cleaner energy solutions that offer greater efficiencies.